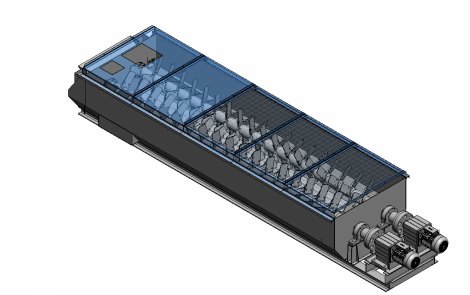

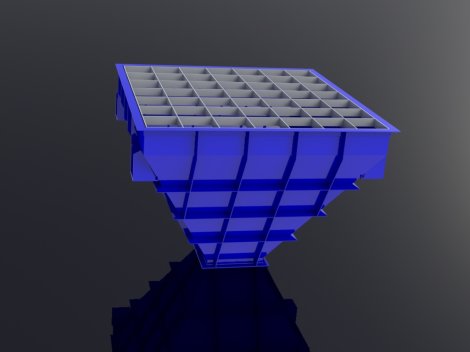

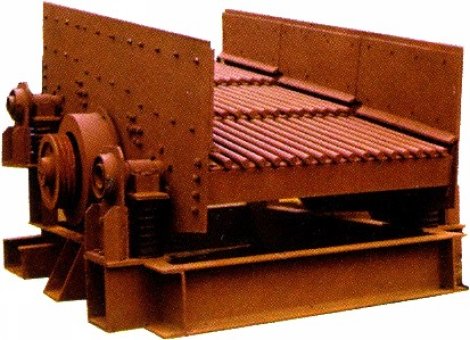

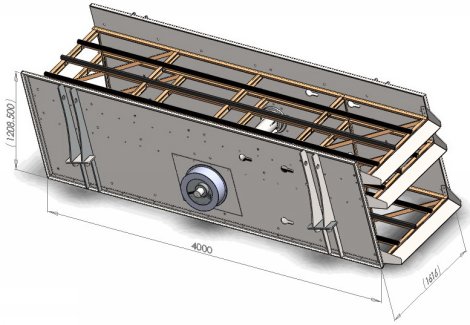

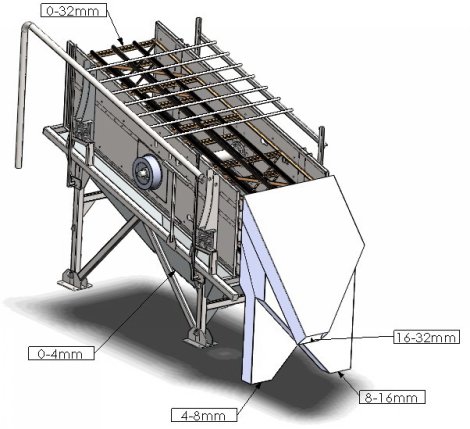

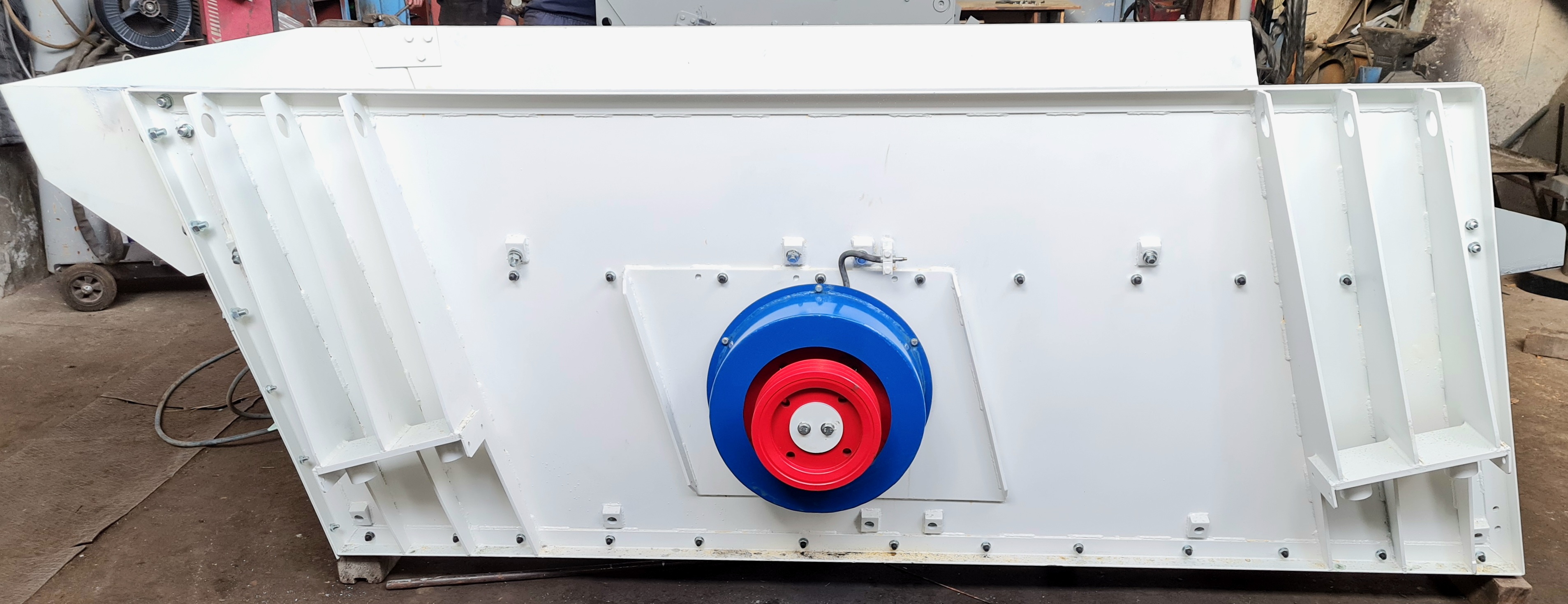

Vibrating screens (eng. Vibrating screens, German Rüttelsieb) are machines that use mechanical vibrations to separate materials by granulation, into fractions. The number of fractions depends on the number of floors of the vibro sieve. Our production program includes screens that can have from one to four floors. They can be used for dry sowing or sowing with washing, with the addition of a washing system. The vibrating screen itself consists of a drive that causes mechanical vibrations, sieving surfaces that separate the material into fractions and a frame that serves as a support for the sifting surfaces and a transport path for vibrations from the drive to the sifting surfaces. The change in the sharpness of the sieve (amplitude) is done by changing the weight of the swing masses (imbalance). Depending on their position in the technological line, they are divided into primary or secondary vibrating screens. They can also be used to separate water from materials using "rhyme" nets.

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|