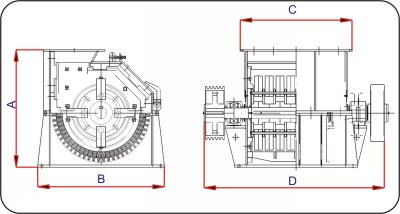

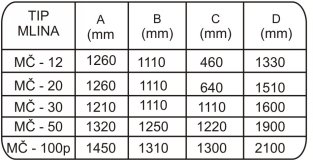

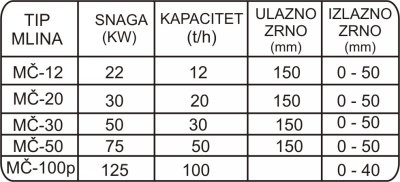

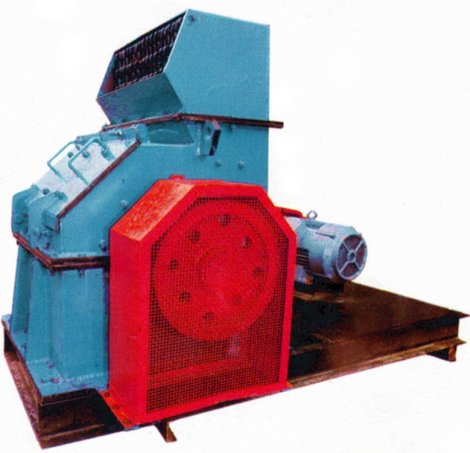

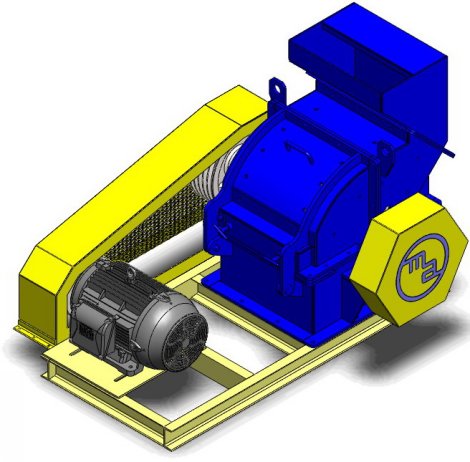

Family of mills with impact beams - MG

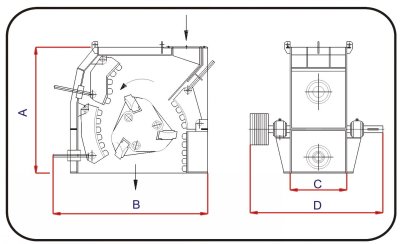

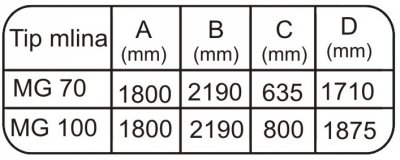

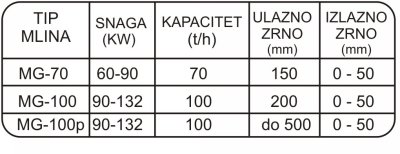

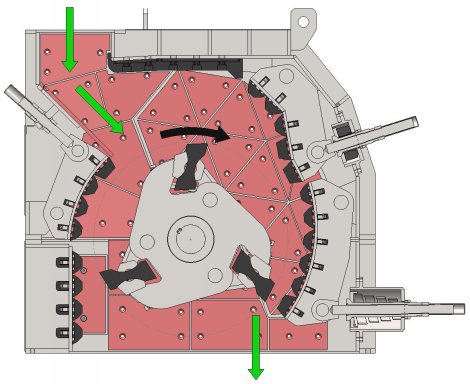

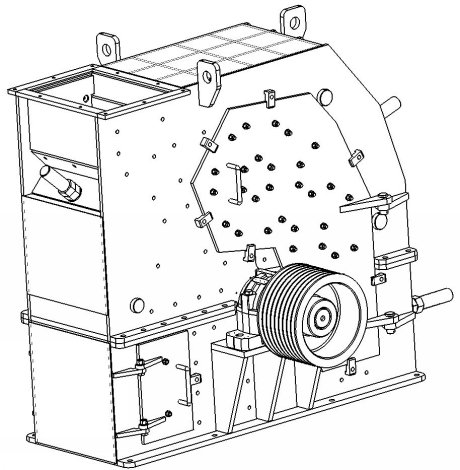

Impact mills are modern solutions of crushers for stone and other crushing materials. Three impact beams are symmetrically arranged on the rotor. The stator consists of a housing completely lined with wear-resistant materials. Gives a cubic grain shape, compact grain (no micro-cracks). Possible crushing of materials mixed with clay or other adhesives. By opening the side door, unobstructed access to all elements of the mill is provided, which makes maintenance extremely easy.

It is recommended for crushing medium-hard to hard materials, less abrasive materials. The most common application is for medium and fine crushing.

It is recommended for crushing medium-hard to hard materials, less abrasive materials. The most common application is for medium and fine crushing.

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|