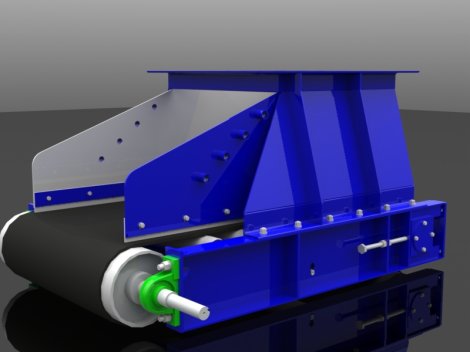

Vibrating feeders

Vibrating feeders are devices for even dosing of granular materials. The vibrating feeder consists of a trough made of steel sheet, along which the material whose dosing is performed slides. An eccentric vibrator (vibro motor) is attached to the trough. The feeder hangs on coil springs, just below the hopper opening. Rough dosing control is performed by adjusting the imbalance (flywheel mass), while fine control is performed by changing the speed of the vibro motor.

They are characterized by high capacities with low energy consumption

They are characterized by high capacities with low energy consumption

×

|

×

|

×

|

×

|

×

|