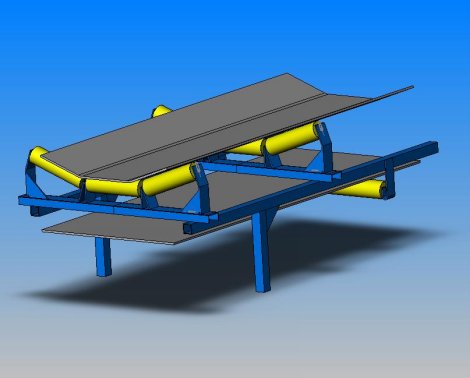

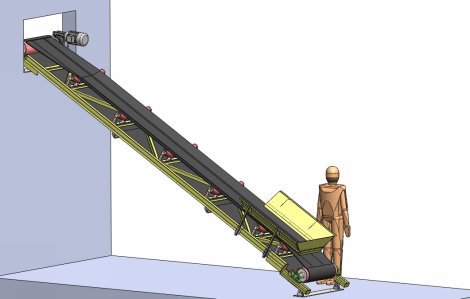

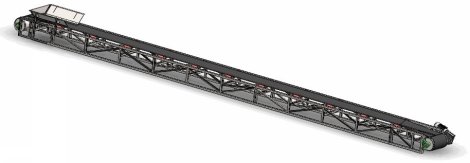

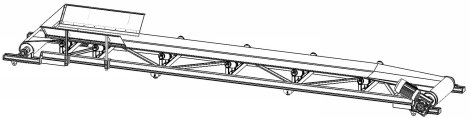

Conveyors with rubber belt

Belt conveyors with a rubber belt are the most common type of belt conveyors. Their advantages over other conveyors are:

- universality in terms of transported material (bulk, piece, packaged)

- high transport speeds, large capacities and long transport distances

- simple construction in which a scale for capacity control can be installed

- relatively small mass reduced to capacity and transport distance (mass / unit of capacity)

- low maintenance costs and, depending on the installation site, good access to the structure

- Possibility to adapt the route line to the terrain

- there is a possibility for automatic regulation and control

- damping of impact loads at the points of material reception achieved by the elastic rubber band or, if necessary, by the installation of rolls with rubber rings

Each of our conveyors can, depending on the need, be equipped with auxiliary devices, such as: transfer basket, material delivery devices (removers), belt cleaners and covers.

- universality in terms of transported material (bulk, piece, packaged)

- high transport speeds, large capacities and long transport distances

- simple construction in which a scale for capacity control can be installed

- relatively small mass reduced to capacity and transport distance (mass / unit of capacity)

- low maintenance costs and, depending on the installation site, good access to the structure

- Possibility to adapt the route line to the terrain

- there is a possibility for automatic regulation and control

- damping of impact loads at the points of material reception achieved by the elastic rubber band or, if necessary, by the installation of rolls with rubber rings

Each of our conveyors can, depending on the need, be equipped with auxiliary devices, such as: transfer basket, material delivery devices (removers), belt cleaners and covers.

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|