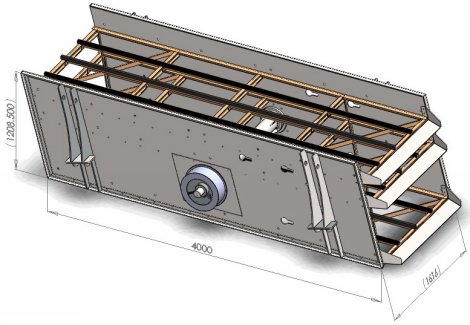

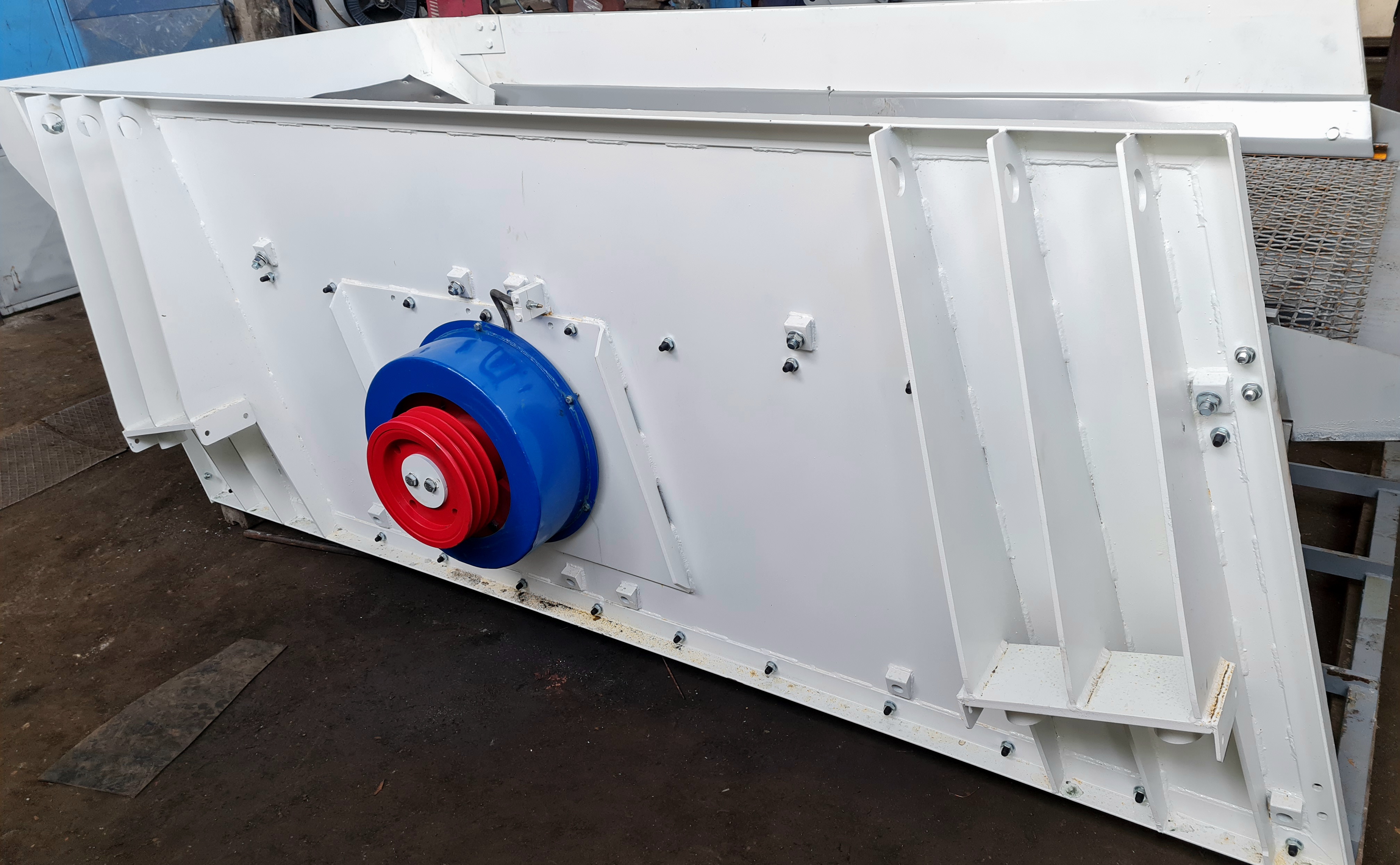

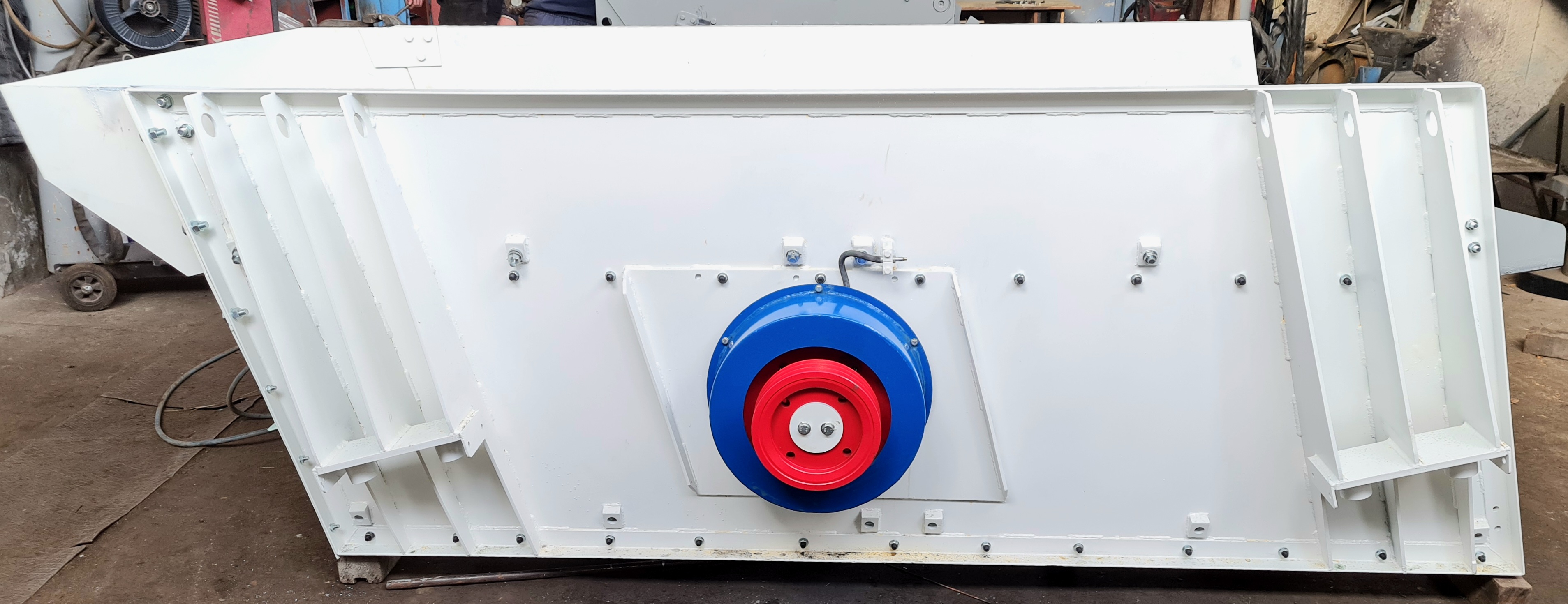

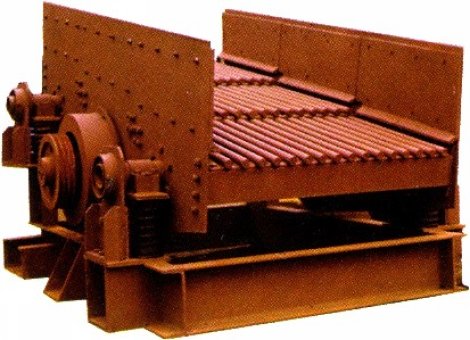

Vibro grate

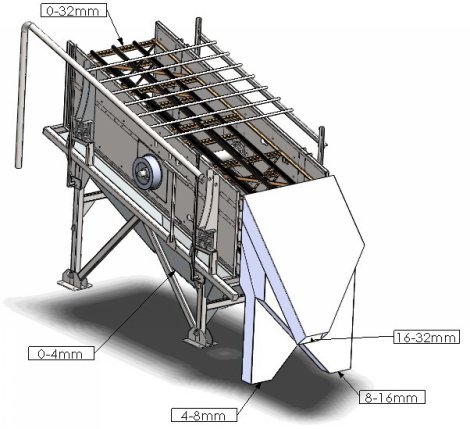

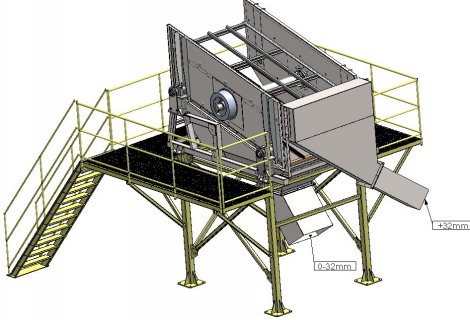

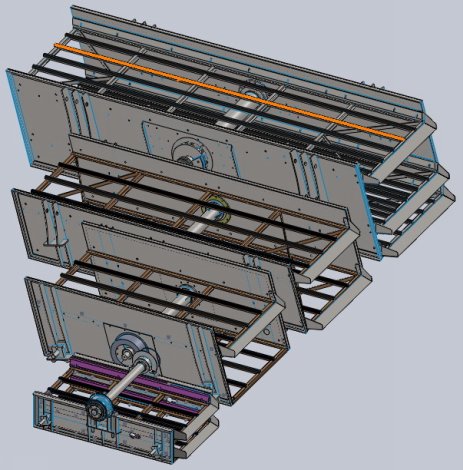

Vibro grate is a machine that uses vibrations to classify and purify materials in the technological process of crushing and separation. Since it is used to separate large pieces, the average surface is a grid made of wear-resistant material. The distance between the grids determines the grain size in the fractions. In the process of separating natural gravel, they are used to separate grains with a size larger than the maximum allowed (iberlauf), and in the process of crushing, they are used to separate tailings. The sieving that precedes the crushers relieves them of the incoming ore mass, which increases the capacity of the crushing department. They can also be made as two-storey, where the upper floor is a lattice, and the lower floor is made of wire mesh and serves to separate another fraction.

In the technological line, they are located behind the bunker, and in front of the secondary sieves or mills.

In the technological line, they are located behind the bunker, and in front of the secondary sieves or mills.

×

|

×

|

×

|

×

|

×

|

×

|