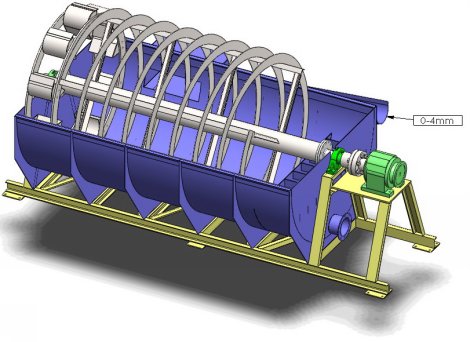

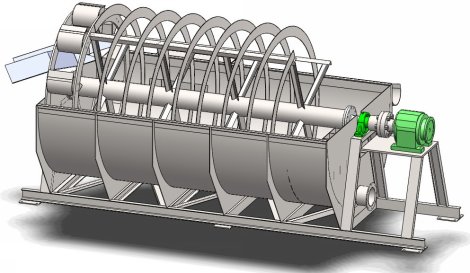

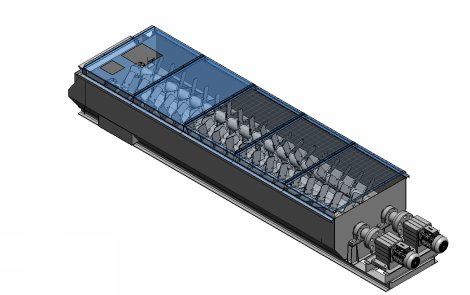

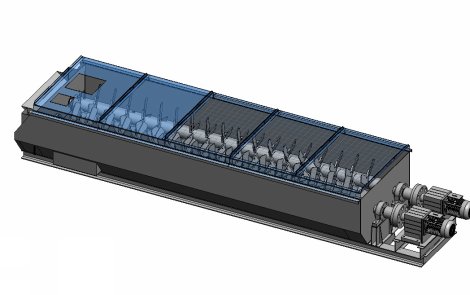

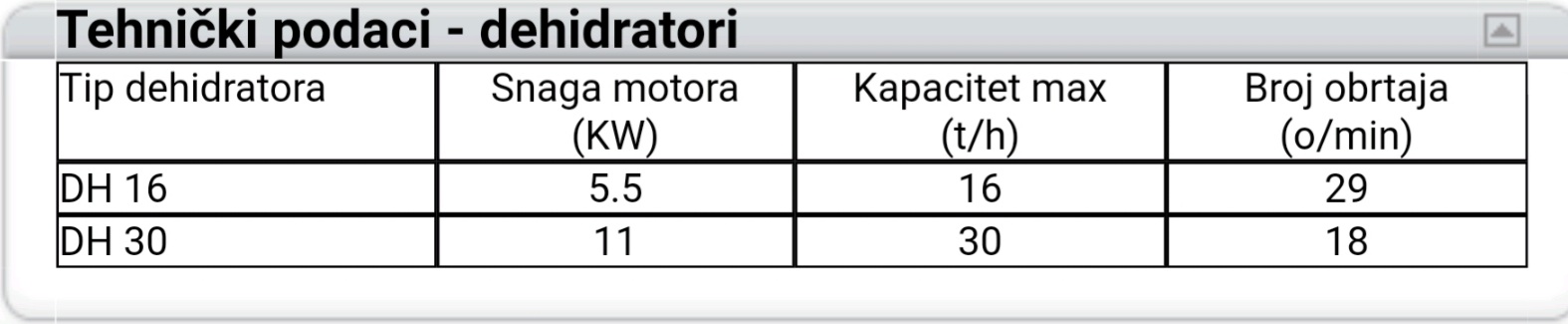

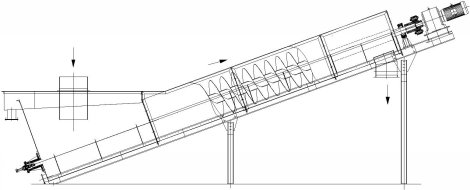

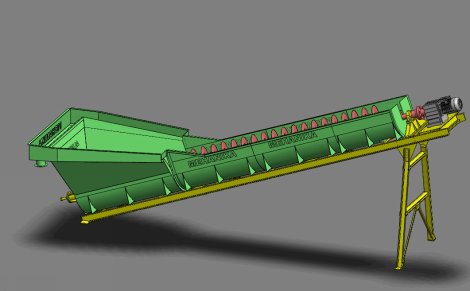

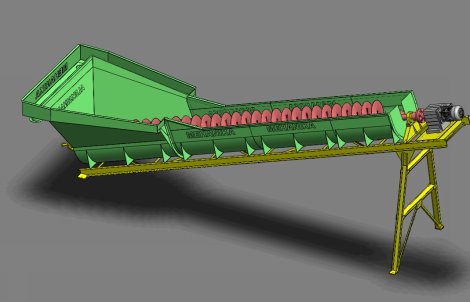

Send washers with spiral

The dehydrator is a spiral classifier that serves to separate the 0-4 mm (0-2 mm) fraction from water after washing the material on vibro screens. The fraction, which has settled at the bottom of the riverbed, is pushed by a spiral towards the upper end of the riverbed. The classifier overflow usually contains 60-80% of the fraction below 0.1mm. Depending on the length of the trough, the moisture content in the finished fraction also changes. In practice, a moisture content of 20-25% is achieved. In order to extend the service life of the spiral, we can protect it by installing wear-resistant steel coatings or plastics - polyurethane

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|

×

|